Leading Power Generation Solutions with PetroGas Libya

Oil and gas Power Generation Solutions involve technologies like gas turbines, compressors, and electric motors to convert fossil fuels into electrical energy, essential for powering equipment and operations. These solutions, crucial for efficiency and sustainability, include converting natural gas to mechanical energy in turbines, managing gas flow with compressors, and using electric motors for mechanical force, supporting various industrial processes in the energy sector from powering offshore drilling platforms to facilitating the transport and processing of oil and gas.

Emphasizing efficiency, environmental sustainability, and reliability, these power generation methods are fundamental in maintaining the robustness and effectiveness of energy sector operations.

Incorporating modern Power Generation Solutions in the oil and gas industry brings numerous benefits, including enhanced efficiency, reduced environmental impact, and increased operational reliability. Advanced technologies like high-efficiency gas turbines, state-of-the-art compressors, and sophisticated electric motors not only optimize the energy conversion process but also minimize greenhouse gas emissions, aligning with global sustainability goals. Regular maintenance of these systems ensures prolonged equipment life, prevents unexpected downtime, and maximizes productivity. This proactive approach to maintenance reduces overall operational costs and improves safety standards, ensuring continuous, smooth, and eco-friendly operations essential in today’s energy landscape.

Precision Monitoring, Trusted Partnerships

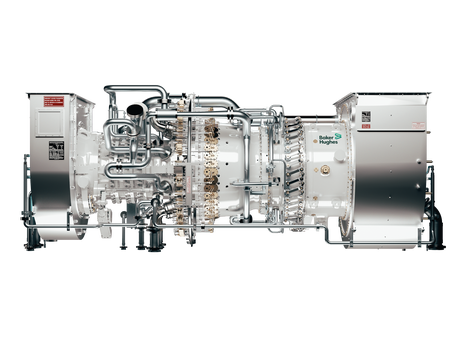

Baker Hughes-Nuovo Pignone gas turbines cover virtually every application across the oil and gas value chain, as well as in other various industries. LNG and pipeline transmission in particular feature some of Baker Hughes’s most famous and innovative solutions.

We approach every machine’s design intending to optimize environmental footprint, operating performance, and total cost of ownership. Beyond core equipment, we have a comprehensive range of supporting systems and specially designed services and upgrades tailored to the unique challenges of each application.

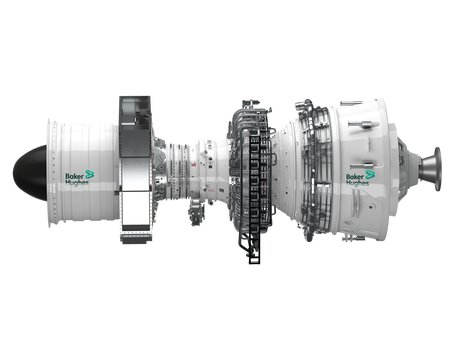

Baker Hughes- Nuovo Pignone steam turbines draw their high efficiency and reliability from decades leading technology development and proven in-field experience of Baker Hughes multiple steam and gas turbine lines.

Baker Hughes modular design approach is extremely flexible in meeting the unique requirements of each project while delivering best-in-class reliability and efficiency. To optimize performance at frequently starting power plants, Baker Hughes units have fast start-up and stress- based rotor control capability.

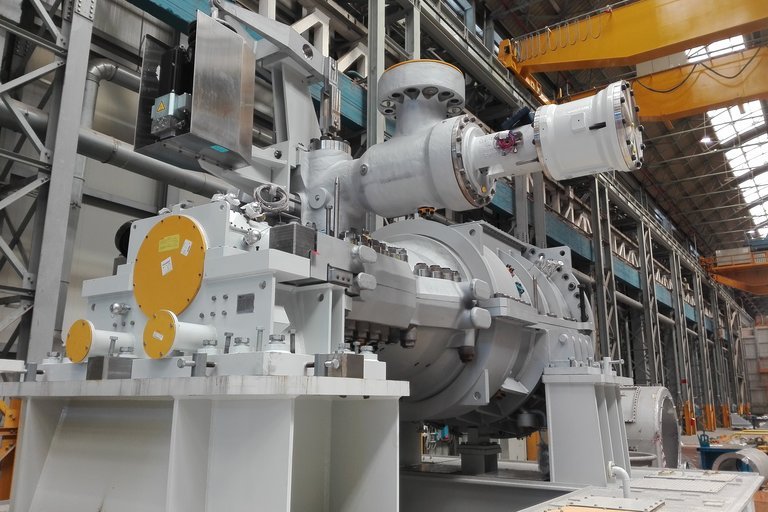

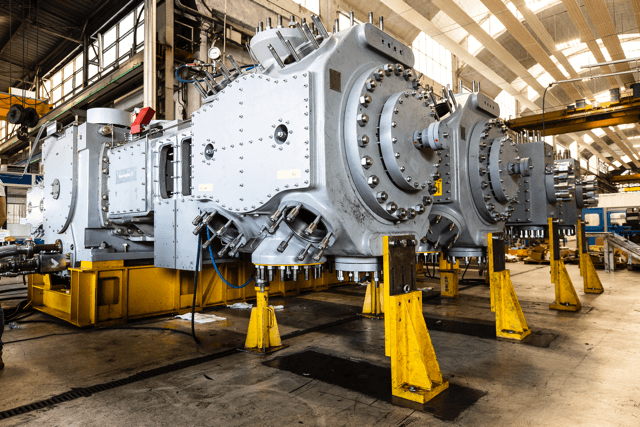

Ranging from the first high-pressure compressor for fertilizer to the most powerful offshore compressor, we have over 5,000 units installed worldwide since 1960. Baker Hughes compression technologies revolutionized large LNG in the 1990s, and we continue to invent, and evolve, taking energy forward.

No matter what the application or challenge, we provide a fully integrated solution to meet your needs—including motor, vessels, piping, supports and control panel. Baker Hughes machines are designed for lower maintenance, operating, and capital costs while boosting the performance of any operation.

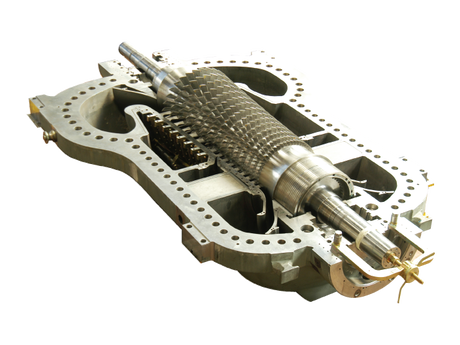

With decades of industry-leading performance, Baker Hughes API618 compressors live up to their reputation for low pulsation and vibration, ensuring exceptional efficiency, smooth operation, low maintenance, and low power consumption. Deployed in full-stream oil and gas applications, Baker Hughes proven modular design allows for up to 10 cylinders per frame, with a cylinder size of up to 1,250 mm.

With a design heritage dating back to 1959, Baker Hughes centrifugal pumps are well-proven in power generation, oil and gas, and industrial applications around the world.

For oil and gas in particular, we make a wide range of API 610/ISO13709-compliant units for hydrocarbon processing, refineries, fertilizers, water injection, and pipeline services.

By leveraging Baker Hughes vast experience with refinery and petrochemical pumps, as well as the research and design practices applied to high-pressure sour gas centrifugal compressors, we’ve executed centrifugal pump projects in various upstream oil and gas applications with

Baker Hughes-Nuovo Pignone gas turbines featuring innovative solutions especially for LNG and pipeline transmission.

Baker Hughes-Nuovo Pignone steam turbines known for high efficiency and reliability, leveraging technology development and in-field experience.

Centrifugal & Axial Compressors for large LNG projects and more.

Reciprocating Compressors designed for lower maintenance, operating, and capital costs while boosting performance across applications.

Centrifugal Pumps API 610/ISO13709-compliant units for hydrocarbon processing, refineries, fertilizers, water injection, and pipeline services.

Mark VIe Control Systems: Advanced control systems for upgrading existing infrastructure, enhancing efficiency, and reliability.

Fire and Gas Detection and Extinguishment Systems: Solutions for fire and gas detection along with modern extinguishing systems.

Motor Control Centers (MCC) and Generator Control Panels (GCP): For controlling motors and generators with updated technology.

Solutions for CTRL Systems Re-Instrumentation and Re-Wiring: Comprehensive solutions to update and improve control systems and electrical wiring.

Upgrades for centrifugal compressors to meet new operating conditions or improve efficiency and operability.

A broad range of products tailored to the power generation sector, including new units and after-sales products.

PetroGas Libya, leveraging its partnerships with Baker Hughes and Nuovo Pignone, is positioned to provide leading power generation solutions in Libya and North Africa. By combining Baker Hughes’ advanced technology and Nuovo Pignone’s expertise in machinery manufacturing with its own extensive experience and local knowledge, PetroGas Libya offers a range of power generation services. These services are tailored to meet the region’s specific energy needs, ensuring reliable and efficient power generation solutions that are vital for the development and sustainability of the North African energy sector.

Baker Hughes offers comprehensive power generation solutions, encompassing various aspects of the power generation sector. Their services include the provision of advanced gas turbines, highly efficient steam turbines, and both centrifugal and axial compressors, as well as versatile reciprocating compressors. These solutions are designed to meet the diverse and evolving needs of the power generation industry, ensuring reliability, efficiency, and sustainability. Baker Hughes’ approach in power generation is focused on delivering technology and services that optimize performance and cater to the global demand for energy.

TBC