Predict, Prevent, Perform with Condition Monitoring

Condition monitoring (CM) is a proactive maintenance strategy that forecasts the health and safety of machinery by integrating real-time sensor data, like vibration measurements, with advanced machine monitoring software. This method allows maintenance technicians to remotely track the condition of each machine and provides a comprehensive view of mechanical operations across the plant. The condition monitoring software issues alerts when there are changes in machine health, empowering maintenance teams to quickly evaluate the issue and decide if immediate corrective measures are needed.

Condition monitoring represents a significant advancement for manufacturers, enhancing safety and reducing risks. It allows plant managers to prevent unexpected downtime by identifying potential machine failures, optimizing planned maintenance, and addressing multiple issues simultaneously. This approach also cuts down on the costs incurred from unnecessary maintenance based on operating hours alone. While condition monitoring is well-established in industrial maintenance, its application is expanding across various manufacturing sectors. Modern condition monitoring systems offer substantial financial and operational benefits, as well as improved safety. For manufacturers embracing condition-based maintenance, the rewards are substantial with minimal risk.

Precision Monitoring, Trusted Partnerships

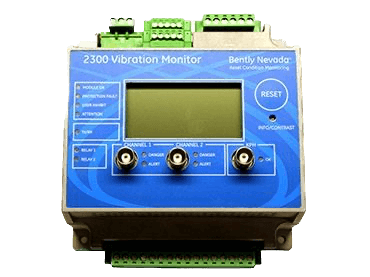

3500 Machinery Protection System: This is a flexible, modular system designed for monitoring and protecting machinery against unexpected downtime and damage. It includes rack-based monitoring for various parameters like vibration, temperature, and rotational speed, ensuring comprehensive protection.

ADAPT Overspeed/ESD System: This system is designed for machinery where overspeed protection is critical. It offers reliable emergency shutdown capabilities to prevent catastrophic failures in high-speed rotating equipment.

Orbit 60 Series: This series represents the next generation of machinery monitoring and protection. It is highly scalable and supports various sensor types, making it suitable for a wide range of industrial applications.

Trend Master Pro: This innovative online vibration monitoring system inks hundreds of permanently mounted transducers and full-waveform and spectrum data to our System 1 software, with its intuitive interface for tracking, alerting & analyzing machinery behaviour.

VB Online Pro Plantwide Condition Monitoring:This system was designed to monitor the condition of machinery with rolling element bearings and complex gear trains.

Scout 200 and vbX Series: These are portable vibration testers designed for on-site analysis. They are capable of capturing vibration data and diagnosing issues in machinery. The Scout 200 series is known for its user-friendly interface and comprehensive diagnostic capabilities.

ADRE Machine Data Acquisition System: This diagnostic system is used for advanced data collection and analysis. It’s particularly suitable for complex machinery and critical assets, providing detailed insights into the health and performance of the equipment.

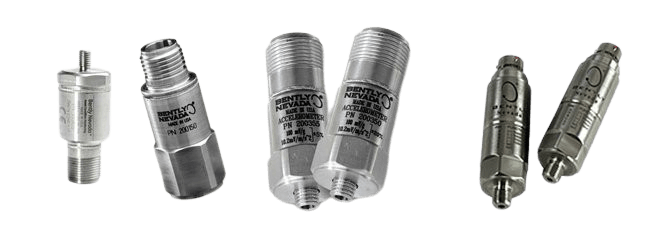

Acceleration Velocity and High Temperature Sensors: Our Am Series Accelerometers, including the High Temperature Acceleration System (HTAS) and High Temperature Velocity and Acceleration Sensor (HTVAS), are designed to measure both acceleration and velocity, providing critical data on machinery vibrations and potential imbalances.

Hydro Sensors: Bently Nevada’s family of Hydro Sensors, specifically used for monitoring moisture and water presence in oil and other fluids, essential for ensuring the health and longevity of machinery.

Pressure Sensors: Bently Nevada’s family of Pressure Sensors monitor the pressure within systems, vital for many industrial processes to ensure safe and efficient operations.

Proximity Sensors: Bently Nevada collection of industrial pressure sensors and transducer systems used to measure the position or change in position of a component, crucial for detecting alignment and displacement issues.

Transmitters: Bently Nevada’s industry-leading transmitters, the 990 Vi-bration Transmitter and the 991 Thrust Transmitter, convert various types of measurements into signals that can be interpreted for monitoring and analysis.

Velocity Sensors: Focused on measuring the velocity of moving parts, these sensors are key in identifying changes in machine performance and potential issues.

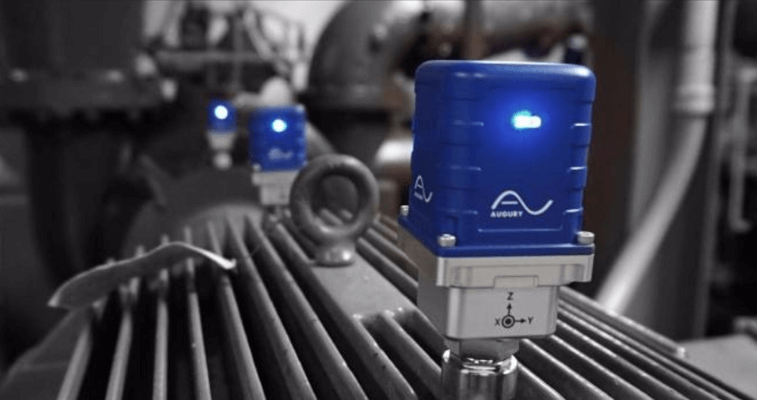

Machine Health Powered by Augury with the deep domain expertise of Bently Nevada along with the Internet of Things (IoT) and Artificial Intelligence (AI) technology combined with System 1 Performance and Predictive Emission Monitoring System (PEMS).

VitalyX, the revolutionary digital lubrication oil monitoring system from Bently Nevada, in partnership with Shell. Lubrication oil is not only the lifeblood of your machines, but it is a key indicator of potentially unseen issues which can cause reduced asset performance or catastrophic loss of assets.

Asset Performance Management at PetroGas Libya encompasses a holistic approach. Asset Strategy Management ensures optimal asset performance by structuring industrial asset reliability strategies. Asset Health Management, pioneered by Bently Nevada, revolutionizes the concept of Asset Management. Defect Elimination focuses on removing failure potentials through a structured process of prioritization, analysis, and efficient problem resolution. Analytic Insights leverage Bently Nevada’s expertise in machine health monitoring, offering comprehensive analytics from edge to cloud for a variety of machinery insights.

Comprehensive diagnostic services for rotating and reciprocating machinery, leveraging a global team of experienced field engineers.

Automated Diagnostics for Rotating Equipment, a leading system for on-demand, flexible, multi-channel machinery data acquisition.

Portable vibration data collectors and analyzers, integrated with System 1 software for route preparation, data analysis, trend detection, and alarm settings.

An all-in-one condition monitoring platform providing connectivity, analytics, and visualization for plantwide asset management, including critical asset monitoring and analytics solutions.

A suite of machine condition monitoring analytics designed to automate failure mode detection across a wide variety of machines, with configurable rules for operational applications.

A multi-plane machinery balancing product integrated with System 1, offering sophisticated tools for efficient machinery balancing.

Techniques for detecting torsional vibrations, crucial for avoiding system reliability issues or catastrophic failures in rotating machinery.

Onsite or remote, portable or online electrical machinery condition monitoring and diagnostics, employing Motor Current Signature Analyses (MCSA) and Model‑Based Voltage and Current Analyses (MBVI).

Advanced rotor modeling tools for understanding machinery behavior, useful for analyzing design or operating changes.

Technology that visualizes minute movements, aiding in diagnosing machinery and structural vibration issues.

Including modal impact testing and operational deflection shape (ODS) analysis for addressing complex interactions of rotating and structural issues.

Standard training imparting machinery diagnostic methodologies, rotor balancing, machinery alignment, and usage of diagnostic tools like ADRE and System 1 software.

A subscription service for hosted infrastructure, software, and asset health management services, delivered through remote monitoring and diagnostics centers.

Offering comprehensive support to maximize the reliability and efficiency of reciprocating machinery, including technical support, software upgrades, and cybersecurity updates.

Tailored diagnostic interfaces for individual assets or entire plants, facilitating quick understanding of asset conditions and required mitigation actions.

Leveraging strategic partnerships with industry giants like Baker Hughes, Bently Nevada, and Nexus Controls, PetroGas Libya excels in delivering top-tier Condition Monitoring solutions. These collaborations bring together advanced technologies and expert insights, ensuring PetroGas offers precision, reliability, and cutting-edge services in equipment health monitoring tailored to its clients’ needs.

Bently Nevada offers Cordant™ Asset Performance Management (APM), a cloud-based solution that integrates health, strategy, and defect elimination for a comprehensive view of asset-related risks and cost optimization opportunities.

Utilizing advanced analytics and connected data, Cordant APM provides insights for intelligent, data-driven decision-making, enhancing continuous improvement and productivity to balance performance, cost, and risk effectively with proven expertise in asset condition monitoring and protection, offering an extensive range of machine monitoring systems and services.

Nexus Controls offers a comprehensive range of control solutions, including Turbine and Compressor Controls, Distributed Control Systems, and Generator Control and Excitation Systems, tailored to diverse industrial needs specializing in delivering custom outcomes using reliable control platforms and OEM partnerships, ensuring optimal performance and ease of operation across various industries.

Additionally, Nexus Controls provides advanced Industrial Cybersecurity and Mechanical, Instrumentation, and Control solutions, integrating with their Nexus OnCore™ Distributed Control System or existing customer systems.

TBC